ماكينة التعبئة على الحافة - SI-150D

طلب:

تُستخدم بشكل أساسي لتعبئة مختلف المنتجات العادية وغير العادية على الحواف. مثل البسكويت والمقرمشات والبسكويت والكعك والخبز الجاف ورقائق البطاطس وما إلى ذلك.

مقدمة

آلة التعبئة والتغليف SI-150D هي حل تغليف أفقي مصمم للمنتجات التي يجب تعبئتها بشكل فردي وعلى حافتها . وهي مناسبة بشكل خاص للمنتجات العادية التي لا تحتاج إلى صواني والتي تتطلب وضعًا ثابتًا ومظهرًا أنيقًا وتغليفًا عالي السرعة.

تعتمد آلة SI-150D عملية تغليف أفقية ، حيث تدخل المنتجات إلى الآلة بشكل أفقي وتُغلّف بغشاء شفاف أو مطبوع. تتميز العبوة النهائية بإحكامها ، وختمها الخلفي الأفقي ، وأختامها النهائية النظيفة ، مما يضمن الحماية والمظهر الجذاب.

طلب

تُستخدم بشكل أساسي لتعبئة مختلف المنتجات العادية وغير العادية على الحافة ، مثل:

- البسكويت

- البسكويت

- ملفات تعريف الارتباط

- بسكويت الكعك

- خبز جاف

- رقائق البطاطس

- ومنتجات مماثلة

نظرة عامة على تغليف التدفق الأفقي

التغليف الانسيابي هو أسلوب تغليف أفقي عالي الكفاءة يُستخدم على نطاق واسع في صناعات الأغذية والسلع الاستهلاكية. يُعدّ جهاز SI-150D مثاليًا للموردين الذين يحتاجون إلى:

- تغليف المنتج بشكل فردي

- توجيه المنتج بشكل ثابت

- جودة إحكام ثابتة

- كفاءة إنتاج عالية

بفضل التحكم المؤازر الكامل والتشغيل الذكي لواجهة المستخدم الرسومية، يوفر جهاز SI-150D المرونة والدقة في الإنتاج اليومي.

ميزات آلة التعبئة والتغليف الأفقية ذات التحكم المؤازر الكامل

نظام سيرفو ذكي

- بنية نظام بسيطة تتكون من محركات مؤازرة، ومحركات تشغيل مؤازرة، وشاشة لمس

- صيغة تحكم الحركة المدمجة بدون وحدة تحكم مستقلة

- أسلاك تعتمد على الموصلات لتصميم صغير الحجم وسهولة الصيانة

- تكلفة تنافسية مع أداء مستقر

سهولة التشغيل

- نظام تحكم ذكي بواجهة المستخدم الرسومية

- إعداد بسيط للمعلمات وتعديل سريع

- واجهة سهلة الاستخدام

مجموعة واسعة من أحجام الأكياس

- يمكن تعديل طول الحقيبة عن طريق تتبع العلامات الملونة أو طول الحقيبة المحدد مسبقًا

- إعداد مرن لأحجام المنتجات المختلفة

تقنية القيادة بدون عمود

- لا توجد وصلات ميكانيكية

- يتم تشغيل كل عمود بشكل مستقل بواسطة محرك سيرفو مزود بمخفض تروس

- دقة أعلى وتآكل ميكانيكي أقل

قاطع ناقل الحركة الأوتوماتيكي

- تغيير موضع القطع أثناء التشغيل

- تم إنشاء منحنى السرعة تلقائيًا

- لا حاجة لضبط الكامة الميكانيكية

أداء عالي السرعة

- أقصى سرعة للخط تصل إلى 50 متر/دقيقة

- أقصى سرعة تعبئة تصل إلى 200 كيس/دقيقة (فك مزدوج)

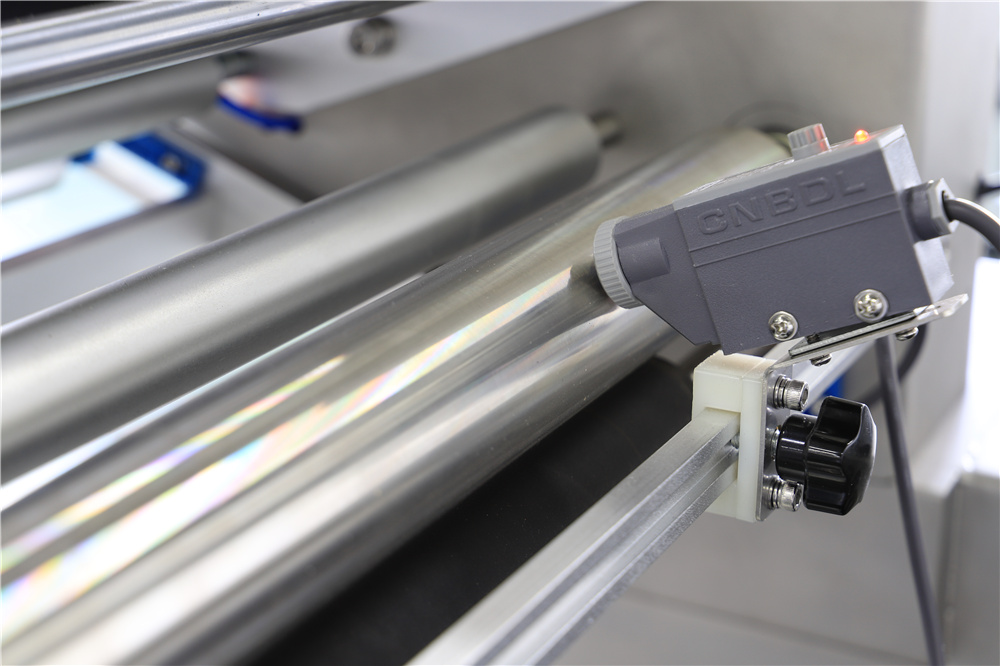

دقة عالية في تتبع علامات الألوان

- دقة التتبع تصل إلى 0.1 مم

وظيفة بدون حقيبة

- يضمن احتواء كل عبوة على منتج

- يزيل الأكياس الفارغة

- يقلل من هدر الأفلام

وظيفة القطع

- يتوقف القاطع تلقائيًا إذا كان موضع المنتج غير صحيح

- تُعاد تشغيل الآلة بعد تفريغ المنتج.

- يمنع تلف المنتج

جهاز وصل الأفلام الأوتوماتيكي

- يقوم بتوصيل لفة الفيلم الجديدة تلقائيًا دون إيقاف الجهاز

- يوفر وقت التشغيل وتكلفة العمالة

حماية عزم دوران القاطع

- يكتشف مقاومة القاطع تلقائيًا

- تتوقف أداة القطع وتعكس اتجاهها عندما تتجاوز المقاومة القيمة المحددة مسبقًا

- قيمة عزم الدوران قابلة للتعديل عبر شاشة اللمس

وظائف خاصة قابلة للتخصيص

- يمكن تعديل الآلة وفقًا لمتطلبات العميل

- أجهزة حماية متعددة للسلامة

- متوافق مع أنظمة التغذية الآلية المختلفة

الميزات القياسية للجهاز

- تصميم آلة صحية لسهولة التنظيف

- هيكل آلة صغير الحجم ذو بصمة صغيرة

- نظام تحكم ذكي مزود بمحركات مؤازرة

- تتبع العلامات اللونية

سهولة التكامل مع أنظمة التغذية الأوتوماتيكية من Soontrue والمعدات الموجودة في اتجاه المنبع أو اتجاه المصب

الصيانة والتفتيش

الصيانة اليومية أو الصيانة الدورية

- نظف الآلة بعد كل عملية تعبئة وتغليف.

- أوقف تشغيل الطاقة واترك الأجزاء الساخنة تبرد قبل التنظيف.

- لا ترش الماء أو البخار مباشرة على الجهاز

أهم نقاط التنظيف:

- قم بإزالة بقايا المواد على ناقل التغذية باستخدام الهواء المضغوط

- نظف سطح القاطع بفرشاة سلكية وزيت السيليكون. ...

- امسح لوحة التحكم وأغطية الأمان بقطعة قماش ناعمة.

- نظف الحلقة الموصلة لأدوات الختم أسبوعيًا أو كل أسبوعين

الصيانة الشهرية

- قم بتشحيم محامل مانع التسرب الطرفي

- قم بتشحيم التروس والسلاسل والبكرات.

- افحص وشدّ السلاسل والأحزمة.

- افحص جميع المثبتات وقم بربطها بإحكام.

الفحص نصف السنوي

- افحص واستبدل أحزمة القيادة البالية

- افحص بكرات المطاط التي تؤثر على تغذية الفيلم

- اضبط وحدة الفرامل الخاصة بأسطوانة حمل الفيلم

- استبدل الأجزاء البالية أو التالفة

- افحص أطراف الأسلاك ونظف المكونات الكهربائية بالهواء المضغوط

التعليمات

س1: ما أنواع آلات تغليف المواد الغذائية التي لديكم؟

الإجابة: نوصي بنماذج مناسبة بناءً على خصائص منتجك وحجمه وطريقة تركيبه، مثل الآلات المزودة بوحدة تحميل علوية للفيلم، أو وحدة تحميل سفلية للفيلم، أو نظام إغلاق طرفي دوار، أو نظام إغلاق طرفي بحركة صندوقية. كما تتوفر أنواع مختلفة من ناقلات التغذية، بما في ذلك النوع السلسلي، والنوع الحزامي، والنوع الذي يغذي الفيلم.

س2: أنا قلق لأنني لا أعرف كيفية تشغيل جهازك.

الجواب: لا داعي للقلق. آلات التعبئة والتغليف لدينا تعمل بنظام تحكم مؤازر كامل، مما يُسهّل تشغيلها وتجهيزها بشكل كبير. تُنجز معظم العمليات اليومية عبر أزرار التشغيل والإيقاف وواجهة المستخدم الرسومية. تتوفر فيديوهات تعليمية، كما تتيح وظيفة الذاكرة في واجهة المستخدم الرسومية إعادة تحميل المعلمات المحفوظة بسرعة.

س3: إذا اشتريت آلة التعبئة والتغليف الأوتوماتيكية الخاصة بكم، فما نوع الدعم الفني الذي يمكنني الحصول عليه؟

الإجابة: نقدم دعمًا فنيًا عبر الإنترنت على مدار الساعة لكل من آلات التعبئة والتغليف المُخصصة وأنظمة التعبئة والتغليف الأوتوماتيكية. تتوفر فيديوهات توضيحية للتركيب والتشغيل والصيانة. كما يُمكن ترتيب خدمات ميدانية للمشاريع المُخصصة (يتحمل المشتري تكاليف الخدمة).

س4: كيف نبني الثقة في أول مشروع تجاري؟

الجواب: نؤمن بأن الثقة تُبنى على الخدمة الاحترافية والمنتجات الممتازة. يمكننا ترتيب جولات تعريفية بالمصنع عبر مكالمة فيديو، وإجراء اختبارات قبول المصنع، أو تقديم فيديوهات تجريبية قبل الشحن لضمان تلبية الآلة لتوقعاتكم.

س5: كيف يمكنني العثور على آلة التعبئة والتغليف المخصصة التي أحتاجها؟

الجواب: سنزودكم بكافة معلومات منتجكم، ونظام التغليف، وطريقة التغذية. وبفضل خبرتنا التي تمتد لما يقارب 30 عامًا في مجال تصنيع آلات التغليف ، يمكننا تقديم فيديوهات توضيحية لحالات مشابهة، وإجراء اختبارات على عينات عند الحاجة لتحديد الحل الأمثل.

شركة Soontrue لتصنيع آلات التعبئة والتغليف بتقنية Flowpack

تُعدّ Soontrue شركةً رائدةً في تصنيع آلات التعبئة والتغليف بتقنية التدفق، ولديها خبرةٌ تمتدّ لثلاثة عقودٍ تقريباً في البحث والتطوير والإنتاج والمبيعات والخدمات. وبفضل خطوط التجميع الروبوتية المتطورة، تستطيع Soontrue تجميع الآلة في غضون 30 دقيقة فقط، ما يضمن جودةً ثابتةً وجداول تسليمٍ موثوقة.

بفضل إنتاجها السنوي الذي يصل إلى 5000 مجموعة من آلات التعبئة والتغليف ، توفر شركة Soontrue للعملاء في جميع أنحاء العالم حلول تعبئة وتغليف فعالة وعالية الجودة.

حافظ على قدرتك التنافسية مع آلات التعبئة والتغليف من Soontrue - المصممة لتعزيز كفاءة التعبئة والتغليف، وحماية جودة المنتج، والارتقاء بعرض المنتج.

| نموذج | سي اي-150 دي |

| نطاق حجم التعبئة | طول 130-400 مم عرض 30-140 ملم ارتفاع 30-75 ملم |

| سرعة التعبئة | 30-110 كيس/دقيقة |

| عرض فيلم التغليف | 90-400 ملم |

| مواد التعبئة والتغليف | OPP، OPP/CPP، PT/PE، KOP/CPP، PVDC/PVC إلخ. |

| القوة العامة | 9.3 كيلو وات |

| نوع مصدر الطاقة | 1 طور 220 فولت 50 هرتز |

| وزن الماكينة | 570كجم |

| أبعاد الماكينة | 4200 × 969 × 1460 ملم |